Product Description

Product Description

| Car Fitment | Jeep Wrangler |

| OE No. | D3571FJK |

| Speed Ratio | 8*41 |

| Type | Differential Gear |

| Material | 20CrMnTi/ 8620 |

| Hardness | HRC58-62 |

| Treatment | Carburizing,Hardening, tempering,high frequency treatment,black coating,zincing,nickelage |

We can make all kinds of CZPT Wheel Pinion as per your drawing or sample by our DHL account.

| D3571 | 11/41 | CJ5/7/8 CZPT 30 FRONT STD.3.73 72-86 |

| D3571TJ | 11/41 | TJ (97-06) FRONT CZPT 30 3.73 (SHORT STYLE) |

| D3571 | 10/41 | CJ5/7 CZPT 30 FRONT STD.4.10 |

| D3571R | 10/41 | YJ(87-95) FRONT CZPT 30 REVERSE 3.73 XJ(84-91) |

| D3571TJ | 10/41 | TJ (97-06) FRONT CZPT 30 4.10 (SHORT STYLE) |

| D3 0571 | 9/41 | CJ5/7/8 CZPT 30 FRONT STD.4.56 72/86 |

| D3 0571 R | 9/41 | YJ(87/95) FRONT CZPT 30 REVERSE 4.56 XJ(84-91) |

| D3 0571 TJ | 9/41 | TJ(97-06( FONT CZPT 304.56 (SHORT STYLE) XJ(92-01) |

| D30488 | 8/39 | CJ5/7 CZPT 30 FRONT STD.4.88 72-86 |

| D30488R | 8/39 | YJ(87-95) FRONT CZPT DANA 30 REVERSE 4.88 XJ(84-91) |

| D30488TJ | 8/39 | TJ FRONT CZPT 30 4.88 (SHORT STYLE) |

| D3571JK | 8/41 | YJ(07-21) FRONT DANA30 5.13 |

| D35712(47715) | 18/49 | |

| D35373 | 11/41 | YJ/TJ CZPT 35 REAR 3.73 |

| D35411 | 10/41 | YJ87-95 /TJ97-06/XJ93-07 CZPT 35 REAR 4.10 |

| D35456 | 9/41 | YJ/TJ CZPT 35 REAR 4.56 |

| D35488 | 8/39 | YJ/TJ CZPT 35 REAR 4.88 |

| D44373 | 11/41 | TJ REAR CZPT 44 3.73 |

| D44409 | 11/45 | TJ REAR CZPT 44 4.10 22745 |

| D44456R | 9/41 | DANA 44 4.56 REVERSE |

| D44455 | 11/50 | TJ REAR CZPT 44 4.56 22105 |

| D44455X | 11/50 | |

| D44488R | 8/39 | DANA 44 4.88 REVERSE |

| D44489 | 9/44 | TJ REAR CZPT 44 4.88 23053 |

| D44489X | 9/44 | |

| D44488X | 8/39 | RUBICON FROUT/REAR CZPT 44 4.88 |

| D44513R | 8/41 | DANA 44 5.13 REVERSE |

| D44513 | 8/41 | TJ REAR CZPT 44 5.13 |

| D44513X | 8/41 | RUBICON FROUT/REAR CZPT 44 5.13 |

| D5 0571 | Sep-41 | |

| D50488 | Aug-39 | |

| D5571 | Aug-41 | |

| D44-4-373 | Nov-41 | 85719 |

| D44-4-342 | Dec-41 | 80364 |

| D44-4-353 | 46/13 | 75945 |

| D44-4-307 | 43/14 | |

| D44-4-346 | Nov-38 | 84707 |

| D44463 | 37*8 | 74960 |

| D44410 | 41*10 | 80320 |

| D44373 | 41*11 | 22736X |

| D44456 | 41*9 | 85713 |

| D44323 | 42*13 | 28744 |

| D44331 | 43*13 | 23592X |

| D44307 | 43*14 | 22106X |

| D44354 | 46*13 | 22856X |

| D44427 | 47*11 | 23064 JEEP WILLYS 11*47 8125051 ANO 1985(CJ6) |

| D44427X | 47*11 | CHRYSLER |

| D44538 | 43*8 | |

| D44-3-342 | 41*12 | 660150 |

| D6571 | 37*9 | 74905 CZPT 3F,D60-411,9X37 |

| D6571 | 41*10 | 24807(FORD250) |

| D6571 | 41*11 | 25538 |

| D6 0571 | 46*13 | 24813 |

| D6 0571 | 41*9 | FORD F250 |

| D6 0571 X | 41*9 | |

| D6571 | 41*8 | |

| D6571R | 41*8 | |

| D60586 | 41*7 | |

| D6571 | 43*8 | Isuzu NHR,D60-586 7*41 |

| D6571R | 43*8 | |

| D60488 | 39*8 | |

| D60488R | 39*8 | |

| D70488 | 39*8 | 72148 |

| D7571 | 41*10 | 72153 |

| D7571 | 41*11 | 72159 |

| D7571 | 41*8 | 72150 C30/P30 F350 41*8 5.3 |

| D7 0571 | 41*9 | 72152 CZPT F350 75-80 |

| D7 0571 X | 46*13 | 72168 |

| D70-1-410 | 41*10 | 72154 CZPT F350 BAJA 75/80 41*10 4.10 |

| D70586 | 41*7 | 72156 D300/P300 41*7 5.86 |

| D75-410 | 41*10 | BA457171-X CZPT Cargo |

| D75-462 | 37*8 | BA457104-X |

| D8571 | 41*8 | 73168 |

| D8571 | 41*10 | 73200 |

| D8571X | 41*40 | |

| D80430 | 43*10 | 76128 |

| D80488 | 39*8 | 76138 |

| D80463 | 37*8 | 73167 |

| D8571 | 41*11 | 76256 |

| D8 0571 | 46*13 | 73353 |

Company Profile

HangZhou CZPT Machinery is a professional manufacture of spiral bevel gear. The company has CNC milling machine, the GLEASON milling machine, rolling inspection machine, gear measuring center, a full set of metallographic analysis, inspection equipment and other related advanced equipment.

Our company owns gear measuring center equipped with advanced testing machines such as contourgraph, universal measuring microscope and full set netlaaographic analysis detector. According to various technical requirements and through procedures of sampling, special inspection and re-examination, multi-indexes of gears like observation, measurement and tracking can be completed.

With our high quality products, high credibility and trusty cooperation, aiming to be a highly specialized gear manufacturer of high level and all-directional service,we are looking CZPT to your business negotiation and our promising cooperation.

FAQ

Q1: Are your products standard?

A: Our model is standard, if you have specific demand, pls tell us the details.

Q2: What is you main categories?

A: Commercial Vehicles Like Isuzu,Nissan, Hino, CZPT ,Toyota , Mazda ,Suzuki, Agricultural Machinery and Electric Storage.

Q3: If we don’t find what we want on your website, what should we do?

A: You can email us the descriptions and pictures of the products you need, we will check whether we have them.

B: We develop new items every month, and some of them have not been uploaded to website in time. Or you can send us sample by express, we will develop this item for bulk purchasing.

Q4: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q5:Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Cast Steel |

| Customization: |

Available

| Customized Request |

|---|

Shaft Collar

A shaft collar is a common machine component that provides mechanical support to shafts. It is found in motors and gearboxes and serves several important functions. Its design makes it an easy component to install. In addition to providing mechanical support to shafts, shaft collars can also serve as locating components and bearing faces.

Sizes

Shaft collars are complex components with several factors that determine their performance. Typical considerations include the style, materials used, bore size, and shaft geometry. Manufacturers typically have information on these factors on their websites. Users can also contact them for advice. These components are available in different sizes and types.

Shaft collars are available in a wide range of sizes, from 1/8 inch to six inches. They can also be re-bored if necessary. There are two main types of shaft collars. The basic one uses set screws, which may mar the shaft. The other type features a clamp screw and a hinge on one side. This eliminates the risk of losing screws.

The most common types of shaft collars are made from steel or aluminum. Plastic shaft collars are lightweight and inexpensive, but have reduced holding power. Steel shaft collars are more durable and hold their shape without bending. They also tend to be corrosion resistant. The steel grades used can have a big impact on their performance. For example, the 12L14 alloy is easier to machine, but does not do well in welding applications. Stainless steel shaft collars offer enhanced corrosion resistance, but reduced holding power. They are most commonly made from 304 stainless steel.

Shaft collars are an integral part of many mechanical systems. They are used to mount shafts onto flat surfaces and hold mechanical components in place. These accessories are available in a wide range of sizes and styles. Depending on the application, a shaft collar can be made to fit virtually any shaft.

The material used for shaft collars is also an important factor. The material of the shaft collar can make a big difference in the performance of the collar. The screw can be either flat or hex. The material will also determine the holding power. A screw with a hardened center will provide better holding power.

Another factor affecting the holding power of shaft collars is its surface treatment. The most common types are steel, black oxide, and zinc-plated. The latter is beneficial as it reduces the friction coefficient and enhances the holding power. Zinc-plated collars are better corrosion resistant than black oxide. However, the black oxide treatment is more effective because it prevents slippage.

Construction

Shaft collar construction involves the construction of a collar around an underground shaft. This structure consists of steel casing and concrete that extends below the surface of the ground. The concrete may be constructed using conventional or specialty cements. It may also contain accelerators and other additives to improve its holding strength. The concrete may also contain heavyweight or lightweight aggregates for optimal properties.

There are two main types of shaft collars. The double split collar is the most common type. It has a split design in the middle and is fastened using two allen head cap screws on each side. It has greater holding power than a solid collar, and the two-piece design makes it easier to install and replace. In addition, double split collars don’t require disassembling the entire shaft and its components.

There are many factors to consider when selecting a shaft collar. The material, holding power, and surface treatment of the shaft collar will affect its ability to withstand the load without slipping. These factors must match the specifications of the application in order to maximize its safety. A guide can help you choose the most appropriate shaft collar for your needs. The holding power of a shaft collar depends on the material used for construction and the screw size.

Shaft collars are used for a variety of applications that require a secure grip on mechanical components. They can be used on shafts, tubes, piping, and even flat surfaces. Only the highest quality collars are approved for use in industrial settings. These collars help ensure proper alignment of mechanical components and prevent any unnecessary movement. There are three different types of shaft collars. One type is a two-piece collar that is held together by two socket head screws.

Shaft collars may include an extended concrete pad at the surface. This concrete pad can support surface equipment and piping support assemblies. The shaft collar extends below temporary bracing material and within the retainment wall. The extended portion of the collar is then extended into the competent rock. From there, the collar transitions to a shaft lining assembly.

Functions

A shaft collar is a simple device that plays a critical role in a wide variety of industrial applications. Its primary functions are to hold components in place, locate components on the shaft, and form an attachment between a shaft and another component. In designing a shaft collar, a designer needs to consider several factors, including the material, bore size, and geometry of the shaft. It is also important to consider the specific requirements of the system.

Threaded collars are superior to smooth-bore collars in many ways. Threaded collars are more resistant to axial loads than smooth-bore collars, which rely on friction. Because the collar and shaft are threaded, they are practically impossible to move axially without breaking the shaft.

There are many types of shaft collars, each with their own unique properties. Each collar has different applications, and its performance must match the needs of the application. For many applications, holding power is paramount, while other performance factors include weldability, inertia, conductivity, corrosion resistance, and precision of collar-face relative to the bore.

While shaft collars may exert some holding force, they also exert other forces on the shaft. For example, they are ideal for splitting hubs, where they act as interfaces between various components. In addition, their close tolerances allow them to exert minimal force on the hub. This allows them to provide increased holding power while minimizing the force needed to close the hub.

Despite their simplicity, the shaft collar plays a crucial role in machine design. They hold components in place and provide necessary positioning for power transmission. Additionally, they are used as spacers in motor assemblies. And, they can also act as mechanical stops, limiting the movement of the shaft. You can find them in virtually any type of machinery.

Another type of shaft collar is the threaded collar, which can be axially or radially attached to the shaft. Its design has an internal thread that helps to precisely position it along the shaft. Internal threads also offer enhanced support for high axial loads. Internal threads also act as a positive mechanical stop.

Applications

Shaft collars are used in a variety of industrial applications. They serve as accurate stops and easy-to-adjust spacers. They can be used on glass, thin-wall tubing, and plastic. Other applications include optical measuring instruments and positioning systems for MRI machines. These collars are available in different sizes, materials, and styles.

The material used for shaft collars can have a significant impact on their performance. A collar’s holding power is also affected by the strength of its screw. Generally, a collar manufacturer will provide a screw that is compatible with the application. However, in some cases, it is necessary to use a nonstandard screw.

The clamp-style collar is reliable under constant loads, but it may need extra support when shock loads are present. In these situations, a small mass is impacted, and high forces are created. A positive stop can help a clamp-style collar stay in place during such shock loads. Alternatively, a collar undercut on a shaft can provide positive stops in both axial directions.

There are many different shaft collar designs and styles. Choose the right one for your application by considering your specifications. Different styles have different purposes, so consider the type and material that is right for your application. Some manufacturers offer a variety of different styles to choose from. You can visit their website or call their customer service representatives for assistance. This way, you can choose the best shaft collar for your specific needs. These collars are a very important part of many mechanical systems.

Clamp-style collars are an excellent choice when axial adjustment along the shaft is required frequently. These collars are easy to install and remove and do not mar the shaft. In addition, they provide excellent clamping force and impressive holding power. Quick-clamp collars are also a great choice for light-duty applications. They allow for fast and easy adjustment and are particularly useful in packaging and printing industries.

Shaft collars are composed of two components: a central bore and a second component. The first component is preferably made of resilient elastomeric material. The second component is made of a plastic material and has a relative stiffness that helps the shaft collar slide on a shaft without causing too much stress.

editor by CX 2023-05-18

China manufacturer & factory supplier for china in Malappuram India supplier Slewing Ring bearing type 33-1091-01 for Deck Crane without gear one year warranty With high quality best price & service

EPG electricity transmission merchandise are designed to provide each trustworthy overall performance and cost-efficiency. Every merchandise is utility-examined and engineered to satisfy stringent specifications for uniformity in dimension, warmth therapy, tensile energy and other essential characteristics. As a value-successful different created exclusively for standard-duty use, EPG’s expanding line of goods are available in all frequently purchased measurements and specs, such as ball bearings, mounted models, roller chain, seals, gauges, sheaves and more.We have exported our merchandise to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states of america, Canada, etc.

Overview

Swift Particulars

- Relevant Industries:

-

Building Material Shops, Manufacturing Plant, Farms

- Model Identify:

-

OEM

- Application:

-

syf

Adhering to “Survival by Top quality, Growth by Technological innovation & Credit score”, The organization will constantly boost item performance to meet up with the rising customer needs in the rigorous fashion of perform.

- Precision:

-

ABEC3-5-7-9

- Gear:

-

non Gear

- Rolling component:

-

GCr15SiMn

- Material:

-

50Mn/42CrMo/Customized

- Operating tempereature:

-

syf

- Load direction:

-

Radial bearing

- RACEWAY hardness:

-

fifty five~62HRC

- nner and outer ring modulation hardness:

-

229-268HB

- Dimension:

-

1022*1166*56 mm

Offer Capability

- Source Capacity:

- 1500 Established/Sets per Month

Packaging & Supply

- Packaging Information

- 1. Bearing floor is lined with the anti-rust oil initial And then wrapped with the plastic movie

2. And then packed with Kraft paper and specialist belts

3. At last, with wood box entirely at the outer packing to in void the rust or the moist

four. Packaging can be carried out according to customer’s specifications.”>HGB Packaging Information:

1. Bearing floor is protected with the anti-rust oil initial And then wrapped with the plastic movie

two. And then packed with Kraft paper and specialist belts

three. At last, with picket box entirely at the outer packing to in void the rust or the moist

four. Packaging can be accomplished in accordance to customer’s specifications.

- Port

- China any Port

-

Lead Time

: -

Quantity(Baggage) 1 – one hundred >100 Est. Time(days) seven To be negotiated

Online Customization

Solution Description

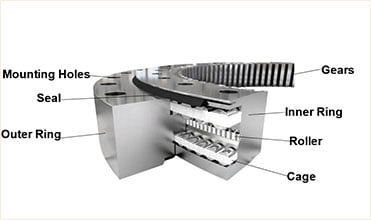

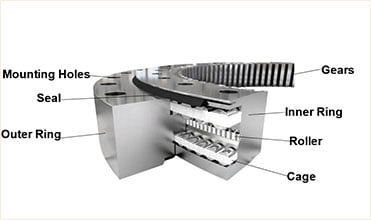

one,Solitary row four position speak to ball slewing bearing

two,Single row cross roller slewing bearing

three,Double-row ball slewing bearing

4,3-row roller slewing bearing

five,Roller/Ball Mix Slewing bearing.

One row 4 point

speak to ball slewing bearing

One row cross

roller slewing bearing

Double Row

Ball slewing bearing

Three row

roller slewing bearing

Roller/Ball Combination

Slewing bearing

|

Sort |

Single row 4 stage get in touch with ball slewing bearing |

|

Rollng aspects |

Steel ball / Cylinder Roller |

|

Rollng aspects Content |

GCr5/GCr15SiMn/Custom-made |

|

Bearing Material |

50Mn/42CrMo/42CrMo4V /Custom-made |

|

Cage Substance |

Nylon/ metal /copper |

|

Structure |

taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

|

Outer diameter |

50-10000mm |

|

Bore dimension |

fifty-10000mm |

|

Mounting gap |

By means of gap/Tapped gap |

|

Raceway hardness |

fifty five-62HRC |

|

Inner and outer ring modulation hardness |

229-269HB/Customized |

|

Equipment type |

No gear ,Interior gear , Exterior gear. |

|

Embellish grease |

EP2 lithium lubricating grease |

|

Certification |

Ab muscles.BV,DNV,ISO9001,GL |

|

Software region |

Ladle turret,Stacker crane,Bucket wheel equipment,Photo voltaic heliostat Monitoring Method,port crane, Cabling device,tower crane , offshore platform,ferris wheel, Palletizing robotic,Rotary metallurgical furnace,can packing machine,Wind blade transporter,defend tunneling machine,tube drive bench,excavator |

|

Brand Name |

HGB |

|

Place of Origin |

HangZhou Henan |

|

Guarantee |

twelve months |

|

Payment term |

T/T is our very first option |

|

Packing information |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie five.Set in wood box |

Product Details

|

Excavator Slewing Bearings are broadly utilised for all makes of excavators, suit for follows designs |

||||||

|

Slewing Bearings For Hita chi |

EX40-1 EX60-1-2-3-5 EX70-5 EX90 EX100-1-2-3-5 EX110-5 EX120-1-2-3-5 EX130-5 EX200-1-2-3-5 EX210-5 EX220-5 EX270 EX300-1-2-3-5 EX-330 EX330-3 EX350-5 EX400-3 EX400-5 EX470-3 EX870 ZAX60 ZX55-R ZAX70 ZAX80 ZAX110 ZAX120 ZAX130 ZAX200-3-6 ZAX210 ZAX220-5 ZAX230 ZAX240 ZAX240-3 ZAX250-3 ZAX270-3 ZAX450-1 ZAX450-3 ZAX450-5 ZAX750 UH063 UH07-7 UH083 |

|||||

|

Slewing Bearings For E |

E45 E60 E70B E80 E110 E120B E305 E311 E312B/C E307B/C/D E308 E315 E200 E200B E320 E320B E320C E320D E320L E324D E325/B/C/D E330/B/C E345/B E350 E365 E380 E385 |

|||||

|

Slewing Bearings For Personal computer |

PC30 PC30-2 PC35 PC40 PC45 PC50 PC50-7 PC55 PC60-5-6-7 PC70 PC75 PC78 PC100-3-5 PC120-3-5-6-6E PC128 PC130-7 PC150-5-7 PC160-7 PC200-1-2-3-4-5-6-7-8 PC210-7 PC220-3-5-6 PC240-8 PC227 PC228 PC270-7 PC300-1-2-3-4-5-6-7 PC350-6-7 PC360-6-7 PC400-3-5-6-7-8 PC450-5-6 PC460-7 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250 |

|||||

|

Slewing Bearings For Sumitomo |

SH50 SH60-1 SH120-1-2/A1/A2/A3/Z3/C3 SH120C3 SH260 SH200 A1/A2/A3/C2/C3/Z3 SH210-5 SH210-A5 SH220-3 SH225 SH240-3-5 SH280 SH350 |

|||||

|

Slewing Bearings For Hyundai |

R55-5-7 R60-5-7 R70-7 R80-7 R110-7 R130-5-7 R130LC-3-5 R150-7 R170-5 R200-3-5-7 R205-7 R210 R215-7 R220-5-7-9 R225LC-7 R260-7 R280 R290-7 R290LC-3 R290LC-7 R300LC R305LC-7 R320 R330LC R335-7 R375 R360LC-7 R450-7 R450LC R962 |

|||||

|

Slewing Bearings For Kato |

DH35 DH55 DH60 DH80-7 DH150-5-7 DH200 DH215-7 DH220-2-3-5-7-9 DH258-7 DH280-5 DX60 DX200 DX225 DX260 DX300 DH280 DH290-5 DH300LC-7 DH340 |

|||||

|

Slewing Bearings For Kobelco |

SK60-3-5 SK100 SK120-1-2-3-5 SK130-8 SK140-8 SK200-6 SK210-6 SK200-6E SK07 SK200-3-5-8 SK210-8 SK220 SK230-6 SK235 SK250-6-8 SK260-8 SK330-6 SK350-8 SK480-eight |

|||||

|

Slewing Bearings For LIUGONG & For XCMG |

CLG9SHAFT Surface area Quality To operate properly and provide satisfactory daily life, oil seals need to have a slender oil movie between the seal lip and mating shaft journal. This situation, identified as hydrodynamic lubrication, wants shaft surfaces that are not perfectly clean but have microscopic pockets to help maintain the lubricant film. Despite the fact that plunge grinding is most widely utilized to finish seal journals, the resulting floor iThe EPG Group variety of PTO shafts equipment consists of various kinds of yokes for the connection of the tractor power get-off with recessed thrust button and/or ball collar and/or ball collar for continual velocity joints, with the pursuing spline dimensions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20s not ideal from this standpoint. Other ending approaches, such as shot peening and liquid honing, give a matte-variety finish which is normally a lot more efficient than a plungeground surface. Even so, even these methods frequently go away lifted, sharp corners that individual the resulting microscopic indentations, yet again providing potential starting up details for leaks.06 CLG907 CLG908 CLG915 CLG915D CLG205C CLG225C CLG220LC CLG225 CLG200 CLG200-3 CLG920D CLG922D CLG925D CLG936LC CLG936D XE60 XE210 XE215 XE150A/B XE230 XE370 210-8 220-eight |

|||||

|

Slewing Bearings For SANY |

SY65 SY75 SY135 SY185 SY195 SY200 SY205 SY210 SY215-7-8-9 SY235 SY300 SY305 SY310 SY335 SY360 SY365 SY420 |

|||||

|

Slewing Bearings For Volov |

EC55 EC210 EC210B EC240 EC290 EC360 |

|||||

|

Slewing Bearings For Liebherr |

R914 R916 R924 R944 |

|||||

|

Slewing Bearings For Yuchai |

YC15 YC20 YC35 YC60 YC6-5T YC85 YC210-8 YC230-8 YC350 YC400-8 |

|||||

|

Slewing Bearings For XGMA and For LONKIN |

XG60 XG808 XG815 XG820 XG822 XG823 XG825 LG6060 LG6075 LG6085 LG6090 LG6210 LG6230 LG6225 LG6235 |

|||||

|

Slewing Bearings For Atlas and For Sunward |

for Atlas3306LC 2006 TC360 2306 SWE50 SWE60 SWE70 SWE80 SWE90 SWE150 |

|||||

|

Much more Versions for |

For LovolFR85 FR150 FR210 For Bobcat80 For SW210 SW230 For Takeuchi135 a hundred seventy five For Scenario CX210B For JCM906D JCM921 JCM922 For EPG75 161 For ZY80 ZY210 For JCB8056 JCB220 For ZW60 ZE80 JV60 SC360 HL60 |

|||||

Bearing Components

Steel ball/Roller:carbon-chromium bearing metal GCr15SiMn or GCr15 for rolling Materials

Cage: consist of integral cage, section cage and spacer-variety cage. 20# steel or copper for integral and section cages, PA 1010 resin or QA110-3-one hundred and five albronze for spacer-type cages.

Seals:uses NBR or VITON, few felted wool.

One row cross roller slewing bearing

Composed of two or 3 rings. compact composition, gentle excess weight, high manufacturing precision, small assembly gap and large prerequisite for set up precision. Rollers are 1:1 cross-organized.

Can be bear axial drive, overturning minute and massive radial drive at the identical time,and widely used in lifting transportation, construction machinery and navy items.

3 row roller slewing bearing

3 row roller bearing in a position to bear all varieties of loads at the identical time, it is the biggest one of the four structural products with huge axle and radial dimensions and agency framework. Specially suitable for heavy machinery demanding bigger diameter, this sort of as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,large machinery and so on.

Solitary row 4 level contact ball slewing bearing

Single row four point composed of two seat rings. has compact construction, mild bodyweight, and 4-stage speak to in between steel ball and arc raceway. It can bear axial power, radial pressure and overturning second at the same time. The development equipment of rotary conveyor, welding manipulator, modest and medium-sized crane and excavator can be chosen.

Why Decide on Us

About Us

Vast creation workshop and sturdy generation group as a assistance,guarantee the items can be produced by needed high quality and amount. andThereby enhance the consumer positive aspects.

The previously mentioned is our manufacturing products with advanced engineering , the secure and longevity bearing generate from these gear .

We specialize in the manufacturing of production slewing ring bearings or turntable Bearings.The Independent R&D and product sales staff in HGB , also do our greatest for specific needsWe provide higher-precision and higher-high quality slewing bearings, which are widly used in many fields,these kinds of as hoisting and conveying machinery, development engineering machinery, harbour machinery, wind electricity generation, radar and missile launchers and so on.

Certification

FAQ

1.Q: Are you trading organization or company ?

A: We are specialist slewing bearing producer with 20 years’ expertise.

2.Q: How lengthy is your supply time?

A: Usually it is 4-5 days if the products are in inventory. or it is 45 days if the products are not in

stock, Also it is according to quantity.

three.Q: Do you supply samples ? is it totally free or further ?

A: Of course, we could provide the sample, it is added.

four.Q: What is your phrases of payment ?

A: Payment=1000USD, thirty% T/T in progress, stability ahead of cargo.

5.Q: Can you give unique customization in accordance to the working situations?

A: Positive, we can layout and produce the slewing bearings for different working circumstances.

6.Q: How about your ensure?

A: We offer lifelong right after-sales technological services.

Speak to Us

Much more Items

A lot more Items

More Goods

Far more Goods